Product Categories

PVDC Coextruded Film

Category:

Product Introduction

Introduction to PVDC High Barrier Film

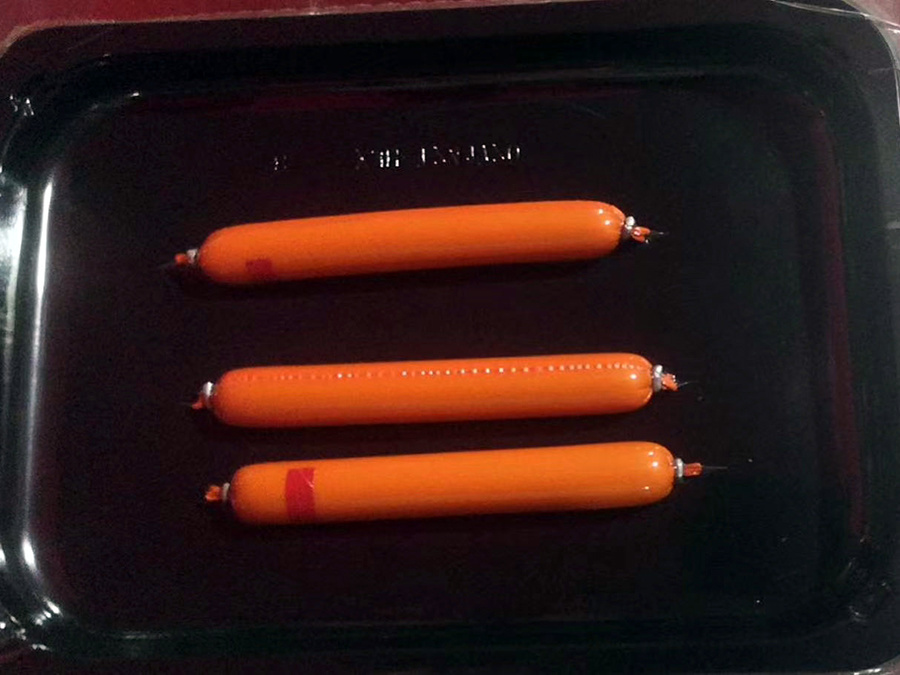

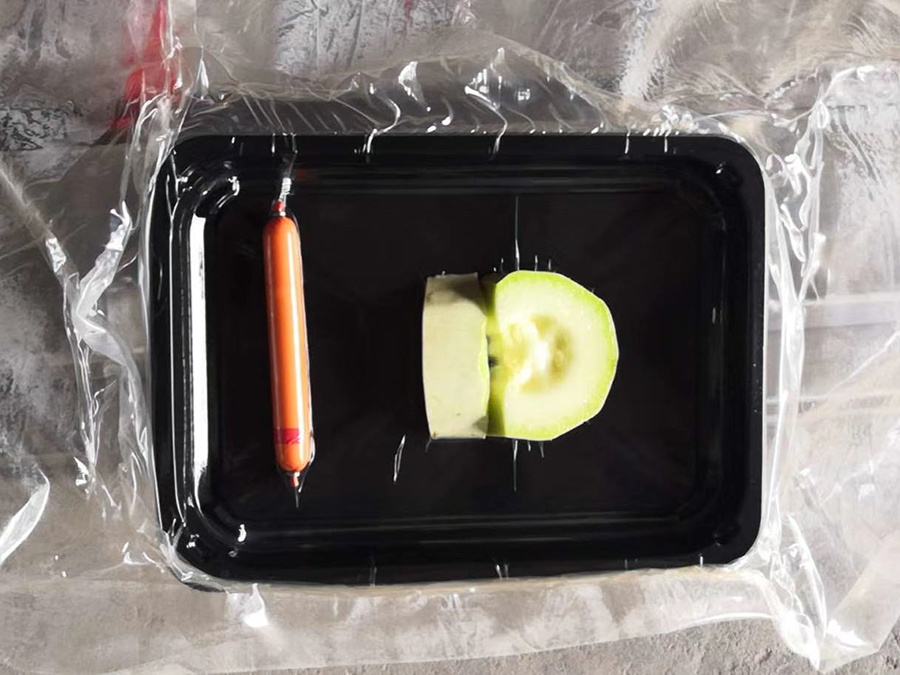

PVDC high barrier film was introduced in the late 1930s. Its early use was for moisture and oxidation protection packaging of military supplies during World War II; later it was widely used for packaging pharmaceuticals, food, chemicals, and electronic devices. As food packaging, PVDC high barrier film helps preserve freshness, aroma, and extends shelf life.

PVDC high barrier film is currently the high barrier transparent material certified by the US FDA for food contact. It is widely used for freshness preservation and odor isolation in pharmaceuticals, food, cigarettes, tea, and beverages, as well as moisture-proof packaging for chemical, electronic, and military products, including shrink packaging, non-shrink packaging, and rigid packaging.

Advantages of PVDC High Barrier Film

1. PVDC is abundant and an energy-saving product.

The raw material of PVDC high barrier film is a copolymer, with 66% of the main raw material derived from sea salt, a component enriched in the ocean; the remaining 34% comes from petroleum or coal, whereas ordinary plastics are 100% petroleum-based. Additionally, the production process involves water dispersion and emulsion polymerization without secondary pollution.

2. Material-saving and less waste.

In PVDC high barrier film, a 5% PVDC layer can extend the shelf life of meat products to 6 months to 1 year, and grains to 3 to 5 years; compared to plastic packaging, its protective function can save 700 times more material than BOPP; thus achieving packaging material reduction and reducing waste at the source.

3. Excellent application performance; shelf life equals value.

PVDC high barrier film can keep pharmaceuticals and food from deteriorating within their shelf life, preventing large amounts of moldy products from becoming waste and harming the environment; the extended shelf life plays an important role in buffering or regulating the market and protecting product circulation.

4. High environmental friendliness

In the United States, PVDC high barrier film is recognized as a non-toxic, safe plastic material, certified by the FDA for food packaging; in Germany, PVDC packaging is included in green packaging and holds the Green Dot mark; in Japan, it has been confirmed that incinerating PVDC products does not affect dioxin emissions.

PVDC high barrier film is a polymer copolymer. Compared with other films, PVDC high barrier film has better transparency, printability (can be printed inside to prevent packaging abrasion and color fading), chemical resistance, toughness, higher impact strength, good heat shrinkability and chemical stability, and can be heat-sealed at low temperatures. Due to its high crystallinity, it features excellent comprehensive barrier properties. Because polyvinylidene chloride resin contains no hydrophilic groups, the product can effectively block water vapor transmission, and its gas barrier properties are not affected by environmental temperature and humidity.

Besides the general properties of plastic products, PVDC high barrier film also has excellent self-extinguishing, oil resistance, flavor retention, and outstanding moisture-proof and mildew-proof performance; it provides excellent protection for the color, aroma, and taste of food, can multiply the freshness and preservation period of food, and significantly reduce food spoilage caused by seasonal changes and other factors.

Therefore, PVDC high barrier film plays an important role in improving the packaging quality of enterprises.

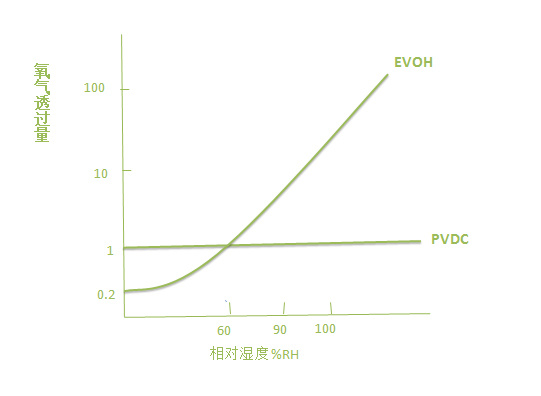

Comparison Chart of Oxygen Barrier between PVDC High Barrier Film and EVOH Coextruded Film

Comparison of Barrier Properties between PVDC High Barrier Film and Other Packaging Films

|

Polymer |

Oxygen |

Water Vapor |

Carbon Dioxide |

Nitrogen |

|

PVDC (MA copolymer) |

0.5-6 |

0.1-0.3 |

0.1-0.5 |

0.1-0.5 |

|

PVDC (VC copolymer) |

43931 |

0.4-1.0 |

0.3-0.7 |

0.1-0.8 |

|

PA6 |

35 |

93-155 |

43-59 |

|

|

PP |

300 |

3.6-10.2 |

1200 |

60 |

|

PET |

74-138 |

27.4-46.7 |

35-50 |

44189 |

|

PVC |

77-310 |

13.2-71.3 |

140-400 |

|

|

LDPE |

500-700 |

15.2-23.4 |

2000-4000 |

200-400 |

|

HDPE |

200-500 |

3.5-11.1 |

2000-4000 |

15-300 |

|

PS |

600-800 |

10.5-33.6 |

2000-4000 |

40-50 |

|

PAN |

11.6 |

31.0-47.2 |

6 |

|

|

EVOH |

0.2 |

47 |

0.9 |

0.02 |

|

(32% Ethylene) |

||||

|

EVOH |

1.8 |

95 |

1.4 |

0.13 |

|

(44% Ethylene) |

Note: Film thickness 25.4um; gas permeability unit cm³/m²*24h*0.1MPa, 50% RH; water vapor permeability unit: g/cm³*24h, 100% RH

From the table, it can be seen that PVDC has excellent barrier properties, exhibiting very high resistance to oxygen, nitrogen, carbon dioxide, and water vapor; compared to other materials, its barrier performance is several to even hundreds of times better.

From the figure, it can be seen that the barrier performance of the PVDC high-barrier film does not change with variations in environmental humidity. Even in high humidity environments such as southern rainy seasons, it still maintains its high barrier properties.

(MA type) PVDC Co-extruded Film Test Analysis Report

1. Performance Comparison of Several Films (Oxygen Permeability Unit: cm3/(m2·24h·0.1Mpa), Water Vapor Permeability (g/㎡·24h))

|

Film |

Oxygen Permeability |

Water Vapor Permeability |

Formability |

Transparency |

High |

Adhesion |

Flexibility |

Prevention of |

Oil Resistance |

Fragrance Retention |

Chemical Resistance |

Protection |

||

|

Before Boiling |

After Boiling |

Before Boiling |

After Boiling |

|||||||||||

|

(MA type) PVDC |

0.8-8 |

Unchanged |

0.8-2 |

Unchanged |

Excellent |

Excellent |

100℃ |

Excellent |

Excellent |

Excellent |

Good |

Excellent |

Excellent |

Excellent |

|

(VC type) PVDC |

4-50 |

Unchanged |

1-6 |

Unchanged |

Good |

Good |

121℃ |

Good |

Good |

Good |

Good |

Good |

Good |

Good |

|

EVOH |

0.2-1.8 |

Greater than 1000 |

20-70 |

- |

Excellent |

Excellent |

100℃ |

Excellent |

Average |

Excellent |

Poor |

Good |

Good |

Good |

2. Partial Performance Comparison of Several Films

|

|

(VC type) PVDC Composite Film |

(MA type) PVDC Co-extruded Film |

EVOH Co-extruded Film |

||||||||||

|

Cover Film |

Base Film |

Cover Film |

Base Film |

Cover Film |

Base Film |

||||||||

|

Tensile Strength, N |

Longitudinal |

67 |

52 |

62.5 |

57.65 |

76 |

109 |

||||||

|

Transverse |

125.5 |

52 |

107.5 |

47 |

72 |

107 |

|||||||

|

Nominal Strain at Break, % |

Longitudinal |

154.5 |

154.5 |

197 |

630.5 |

86 |

553 |

||||||

|

Transverse |

46 |

123.5 |

34.5 |

735 |

83 |

593 |

|||||||

|

|

(VC type) PVDC Composite Film |

(MA type) PVDC Co-extruded Film |

Untreated |

Treated |

|||||||||

|

Untreated |

Treated |

Untreated |

Treated |

Cover Film |

Base Film |

Cover Film (VC type) PVDC Composite Film |

Base Film |

||||||

|

Cover Film |

Base Film |

Cover Film |

Base Film |

Cover Film |

Base Film |

Cover Film |

Base Film |

||||||

|

Oxygen Permeability |

14.017 |

16.89 |

13.186 |

12.990 |

5.249 |

6.328 |

4.294 |

4.468 |

14.745 |

1.858 |

13.464 |

2.219 |

|

|

Water Vapor Permeability |

1.308 |

1.436 |

1.408 |

1.365 |

1.296 |

1.449 |

1.114 |

1.212 |

1.702 |

2.244 |

1.826 |

2.482 |

|

From the above two comparison tables, it can be seen that compared with the common (VC type) PVDC composite stretch film and EVOH co-extruded film, the (MA type) PVDC co-extruded film has advantages such as high barrier, high transparency, softness, body adhesion, easy tearing, and easy stretch forming. Compared with EVOH co-extruded film, its barrier property does not change with environmental temperature and humidity, whereas EVOH co-extruded film's barrier property decreases by hundreds of times under high temperature and high humidity conditions, losing its barrier function; the (MA type) PVDC co-extruded film provides excellent protection for the color, fragrance, and taste of food, can multiply extend the freshness and shelf life of food, and significantly reduce food spoilage caused by seasonal changes and other factors.

Keywords: Masterbatch

Get a Quote

* Note: Please be sure to fill in the information accurately and keep communication open. We will contact you as soon as possible.

Related Products